Product Development

Whether you are starting from a napkin sketch or have a refined design, the manufacturing of a product is likely to require some development activity.

We are experienced in taking a product through the phases of development and commercialization including design, prototyping or production scale up.

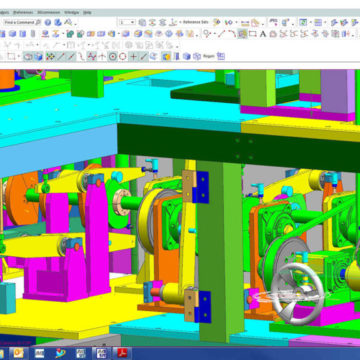

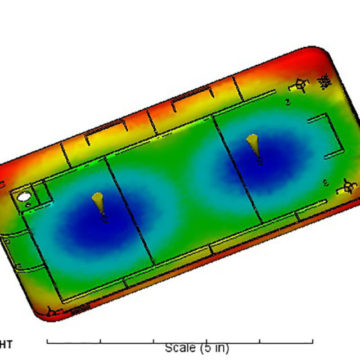

Design / Engineering Analysis

Our team provides design & engineering analysis services as part of broader project involvement or as a stand-alone engineering service. Capabilities include product and tooling design, finite element analysis, mold filling/process simulations and thermal analysis.

Prototype

Protyping a product is a critical step to demonstrate the expected functionality and validate the design.

There are many options for prototyping a product and we can assist, whether it involves machined parts or prototype tools to mold parts.

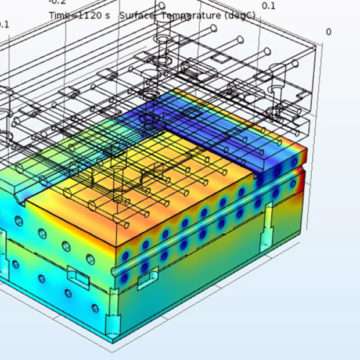

RocTool

Plastics never looked so good. High gloss, detailed textures, improved mechanical properties, no surface defects, no sink marks, no visible weld lines, and no paint solutions. With Roctool technologies, plastics enter the world of high definition.

Advanced Composite Processing

Fast. Temperature Control. High Heat. Roctool induction molding technologies for composites make you forget other limited heating methods.

RocTool technology can be applied to injection and compression molding